|

||

Concrete Mixing Vibrator |

||||||||||||||||

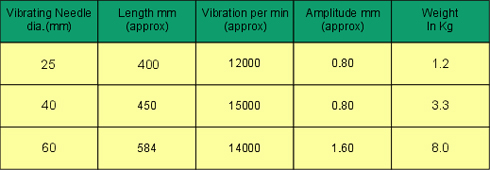

Specification for Needle: |

||||||||||||||||

|

||||||||||||||||

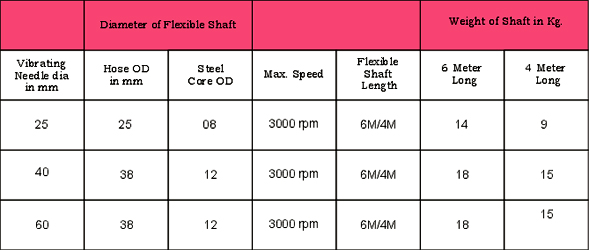

Specification for Flexible Shafts: |

||||||||||||||||

|

||||||||||||||||

Important: |

||||||||||||||||

|

||||||||||||||||

Warning: |

||||||||||||||||

Ensure that the motor runs in clockwise direction when viewed from far end, otherwise the inner core will

unwind causing irreparable damage to flexible shaft. |

||||||||||||||||

| ------------------------------------------------------------------------------------------------------------------------------------------------------ | ||||||||||||||||

|

||||||||||||||||